Dr. Reza Ovissipour is an Assistant Professor in the Department of Food Science and Technology at Texas A&M University, where he leads several federally funded projects focused on Cellular Agriculture, sustainable food systems, and alternative proteins, including insect-based food and feed. He also leads a large USDA-funded project addressing COVID-19 in the food supply chain. Committed to advancing the sustainability, safety, and resilience of the food supply chain, he employs technological innovations and contributes to the education of future professionals in the field.

With over 70 publications in the domains of food systems and food engineering, Reza Ovissipour holds several patents related to nano-based materials, non-living surrogates, and serum-free media for cultivated meat. Additionally, he has founded multiple startup companies and successfully brought various technologies and products to commercialization. Notably, he pioneered the development of the first comprehensive food safety plan for aquaponics and cell-based seafood. Reza Ovissipour earned his Ph.D. in Bioprocess Engineering and another Ph.D. in Biosystems Engineering from Washington State University.

Lab Mission

Our mission is to develop new and smart technologies for reshaping global food systems using Alternative proteins, Insect farming, precision fermentation and Cellular Agriculture.

Our Research

- Enhance Sustainability, Resiliency and Robustness in Agri-Food Systems;

- Cellular agriculture and precision fermentation;

- AI-assisted food production, and improving Life Cycle Analysis;

- Insects-based food and feed production;

- Agri-food waste valorization;

- Bioprocess technology and fermentation to enhance the post-biotics quality;

- Nanobubbles and microbial community for enhancing food production;

- Biomaterials and bioplastics;

- Aquaponics and hydroponics;

Cellular Agriculture

Cellular Agriculture is emerging as a feasible solution to address immediate societal problems by developing new sustainable agri-food systems to feed a rapidly growing global population. This industry will provide nutritious and safe foods for consumer options while reducing environmental impact and resource usage (78-96% fewer greenhouse gas emissions, 99% less land use, and 82-96% less water use). In our lab, we are working on (a) cell line development, (b) media optimization using AI, (c) serum-free media development through fermentation and bioprocessing, and (d) media recirculation system.

Decarbonization, Fermentation, Precision Fermentation and Bioprocessing

We are pioneering an innovative approach to establish a circular economy platform for agri-food wastes and feedstock, transforming them into alternative proteins and peptides for cellular agriculture.

Cell culture media developed from different sources: (A) Sources of raw materials, (B) Cell growth after feeding on different concentrations of protein hydrolysates. Black soldier fly provided the most cost-effective peptides sources as a serum replacer.

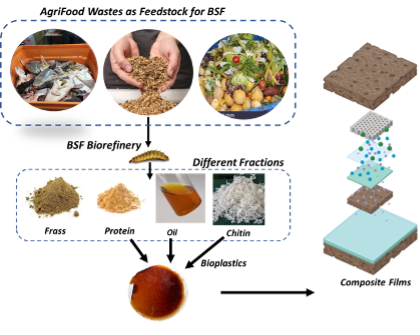

Biomaterials and Bioplastics-Insect as Biorefinery

Worldwide, global plastic production has increased during the past decades from 1.9 tons in 1950 to 335 million tons in 2016. Only in 2019 did the production and incineration of plastic add more than 850 million metric tons of greenhouse gases (GHGs) to the atmosphere—equal to the emissions from 189 five-hundred-megawatt coal power plants.

Aquafeed and Pet Food

We have been developing different aquafeed and pet food products from sustainable biomass sources including sorghum, soy, food industry waste, insects, algae, and cells.

Food Safety Engineering

We have created nanogas-based sanitizers to enhance water quality, ensure microbial food safety on food contact surfaces, eliminate pathogens from leafy greens, and combat microbial biofilms in aquaponics and hydroponics systems.

We are also working on SARS-CoV-2 to address food safety concerns in food supply chain from farm to fork.

Lab Capabilities

- 6 L bioreactor

- Absorbance, fluorescence, luminescence-Microplate reader, gas control, temperature control.

- Inverted Microscope

- Cellular Agriculture lab

- Cell Counter

- Fermentation and Precision Fermentation

- Bioprocessing

- Shared Freeze Dryer

- Shared Autoclave

- Incubators and Refrigerators

- Liquid Nitrogen Tanks (10 to 40 L)

- Nano-gas generator

- Energy Usage Measurement

- Life Cycle Assessment

- Vibrational Spectroscopy and Chemometrics

Ovissi Lab Team

- Dr. Yi-Fan Chen, Research Scientist

- Arian Amirvaresi, PhD student

- Reyhaneh Sarkarat, Masters student

- Julia Fedler, Undergraduate student, Chemical Engineering

Program Alumni

- Dr. Mohammad Zarei, Research Scientist, Alternative Protein

- Dr. Lexi Duscher, Postdoc, Alternative Protein

- Dr. Taozhu Sun, Postdoc, Food Safety

- Dr. Janak Dhakal, Postdoc, COVID-19

- Dr. Samad Keramat, Research Scientist, Alternative Protein and Fish Feed

- Dr. Caio Miyai, Postdoc, Circular Economy and Fish Feed

- Dr. Shabnam Jeibouie, Postdoc, Cellular Agriculture

- Dr. Sheida Hashemi, Postdoc, Cellular Agriculture

- Dr. Inayat Batish, PhD student, Cellular Agriculture

- Thet Aung, Masters student, Cellular Agriculture

- Amiti Banavar, Masters student, Cellular Agriculture

- Palak Garg, Masters student, Cellular Agriculture